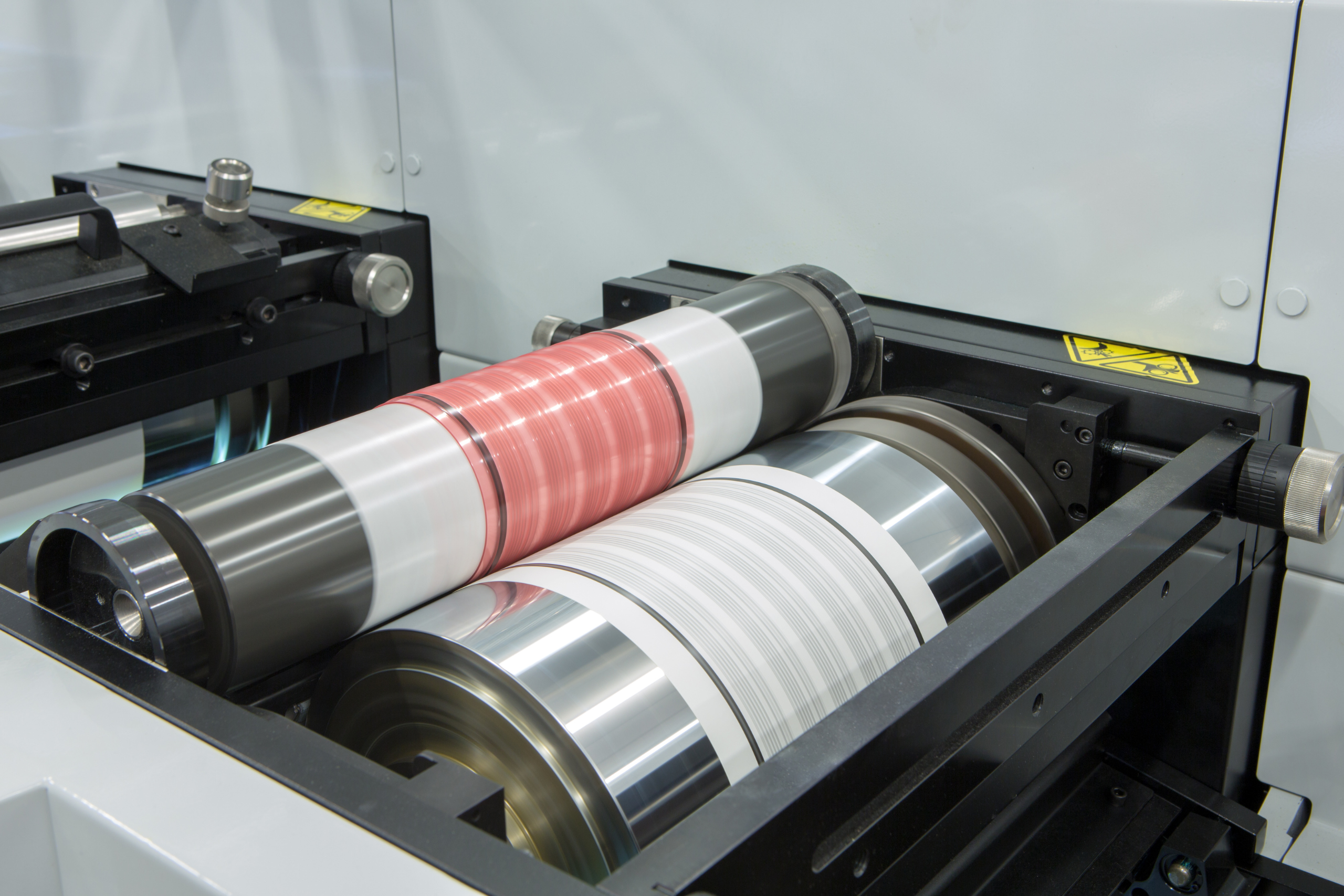

Rotogravure printing is a widely used printing technique for a variety of industries such as packaging, publishing, and decorative printing. It involves engraving an image onto a cylinder and then transferring that image onto the desired material through a series of mechanical and chemical processes. In order to ensure the highest quality of prints and maintain a long-term successful printing process, it is crucial to invest in a durable and high-quality base shell for your rotogravure printing cylinder.

A base shell is the foundation of a rotogravure printing cylinder. It is typically made of high-quality steel, and its surface is carefully prepared to ensure a smooth and even finish for engraving. The base shell plays a critical role in the printing process by providing the necessary support and stability for the engraving process.

Investing in a durable base shell can have a significant impact on the long-term success of your rotogravure printing process. Here are some of the key benefits of using a high-quality base shell:

- Improved Engraving Quality: A high-quality base shell provides a smooth and even surface for engraving. This leads to improved engraving quality, which translates to better print quality and a more visually appealing final product.

- Longer Service Life: A durable base shell is built to withstand the wear and tear of the engraving process, resulting in a longer service life. This reduces the need for frequent replacements and repairs, which can save you time and money in the long run.

- Increased Production Efficiency: A high-quality base shell can improve production efficiency by reducing the need for frequent cylinder changes and repairs. This means less downtime and increased productivity for your printing operation.

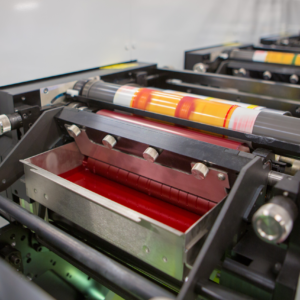

- Better Ink Transfer: A smooth and even surface provided by a high-quality base shell results in better ink transfer, leading to sharper and more vibrant prints.

- Improved Registration: A stable and durable base shell helps to maintain accurate registration during the printing process. This means that each print is precisely aligned, resulting in a more professional and polished final product.

- Enhanced Durability: A durable base shell can withstand the wear and tear of the printing process, which helps to maintain its shape and prevent distortion. This results in a longer service life and reduced need for repairs.

- Improved Safety: A high-quality base shell is designed to be safe and easy to handle, reducing the risk of accidents and injuries during the engraving and printing process.

Investing in a high-quality base shell for your rotogravure printing cylinder is a smart investment in the long-term success of your printing operation. By choosing a durable and reliable base shell, you can improve print quality, increase efficiency, reduce downtime, and ultimately, save time and money.