Rotogravure printing has been around for over a century, providing high-quality printed materials for a variety of industries, including packaging, publication, and decorative printing. The process involves engraving an image onto a cylinder, which is then used to transfer ink onto the printing substrate. However, one of the critical components of the rotogravure printing process is the base shell cylinder. It is the foundation on which the image is engraved and the key to the quality of the final printed product.

In recent years, advancements in base shell technology have led to significant improvements in the efficiency and quality of the rotogravure printing process. Let’s explore how these advancements are revolutionizing the industry.

Improved Durability and Longevity

The quality of the base shell cylinder directly impacts the durability and longevity of the engraving. Traditional base shell materials, such as copper and nickel, are prone to wear and tear, leading to a reduction in the cylinder’s lifespan. However, advancements in base shell technology, such as the use of high-strength steel alloys and coatings, have significantly increased the cylinder’s durability and longevity. This improvement reduces the need for frequent replacements and downtime, ultimately leading to increased productivity and cost savings.

Greater Precision and Consistency

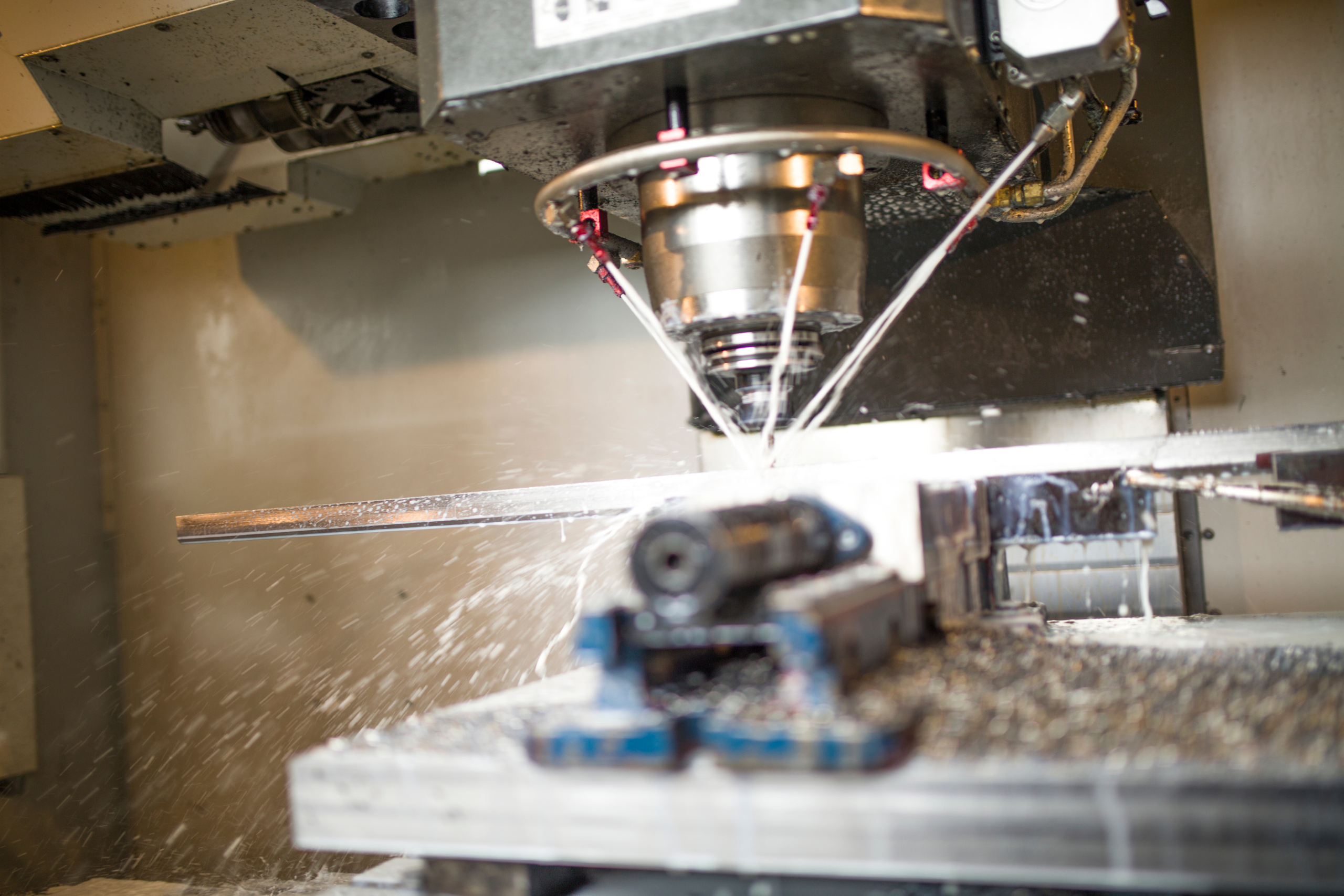

Another benefit of base shell technology advancements is the ability to achieve greater precision and consistency in the engraving process. Precision is critical in rotogravure printing to ensure that the ink is transferred correctly, and the final print is of the highest quality. New base shell materials, coatings, and manufacturing techniques have led to finer and more consistent engraving patterns, resulting in a higher quality of printed materials.

Enhanced Efficiency

Advancements in base shell technology have also led to increased efficiency in the rotogravure printing process. The precision and consistency achieved through the use of modern base shell materials and coatings allow for faster printing speeds and improved ink transfer. Additionally, the increased durability and longevity of the cylinders mean less downtime for maintenance and replacement, resulting in increased production rates.

Expanded Application Capabilities

The use of modern base shell materials and coatings has also expanded the capabilities of rotogravure printing. For example, the use of ceramic coatings has made it possible to print on a broader range of substrates, including plastic films and metallic foils. This expansion of application capabilities opens up new markets and opportunities for the industry.

Conclusion

The advancements in base shell technology have revolutionized the world of rotogravure printing. Improved durability and longevity, greater precision and consistency, enhanced efficiency, and expanded application capabilities have all contributed to the industry’s growth and success. As the technology continues to evolve, we can expect even more significant improvements in the future.

Leave A Comment