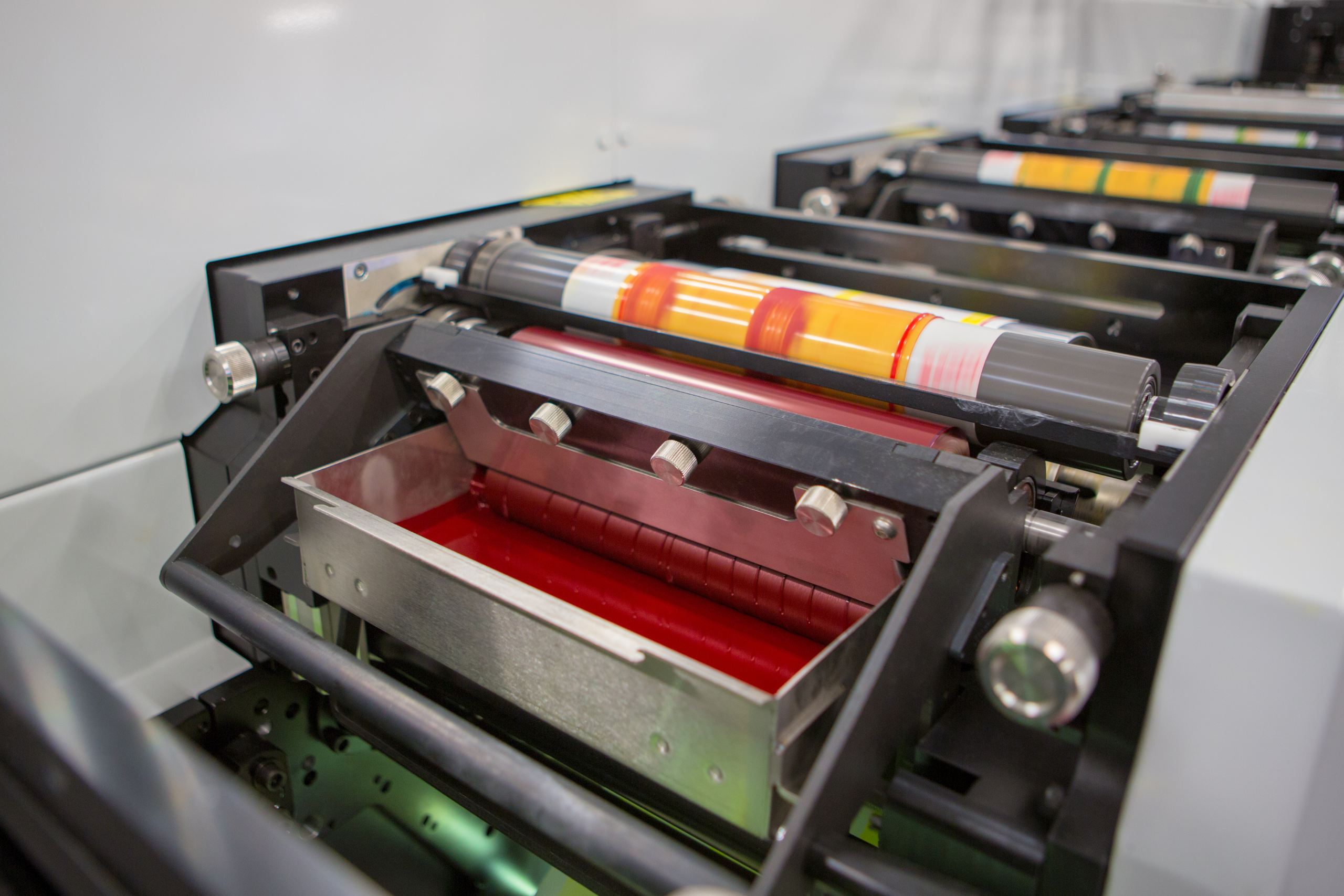

Rotogravure printing is a widely used printing process that utilizes an engraved cylinder to transfer ink onto a substrate. The quality of the engraved cylinder, or more specifically the base shell, plays a crucial role in the printing process. A high-quality base shell can revolutionize the rotogravure printing process, leading to better print quality, reduced downtime, and increased productivity. In this article, we will explore how a high-quality base shell can revolutionize your rotogravure printing process.

What is a Base Shell?

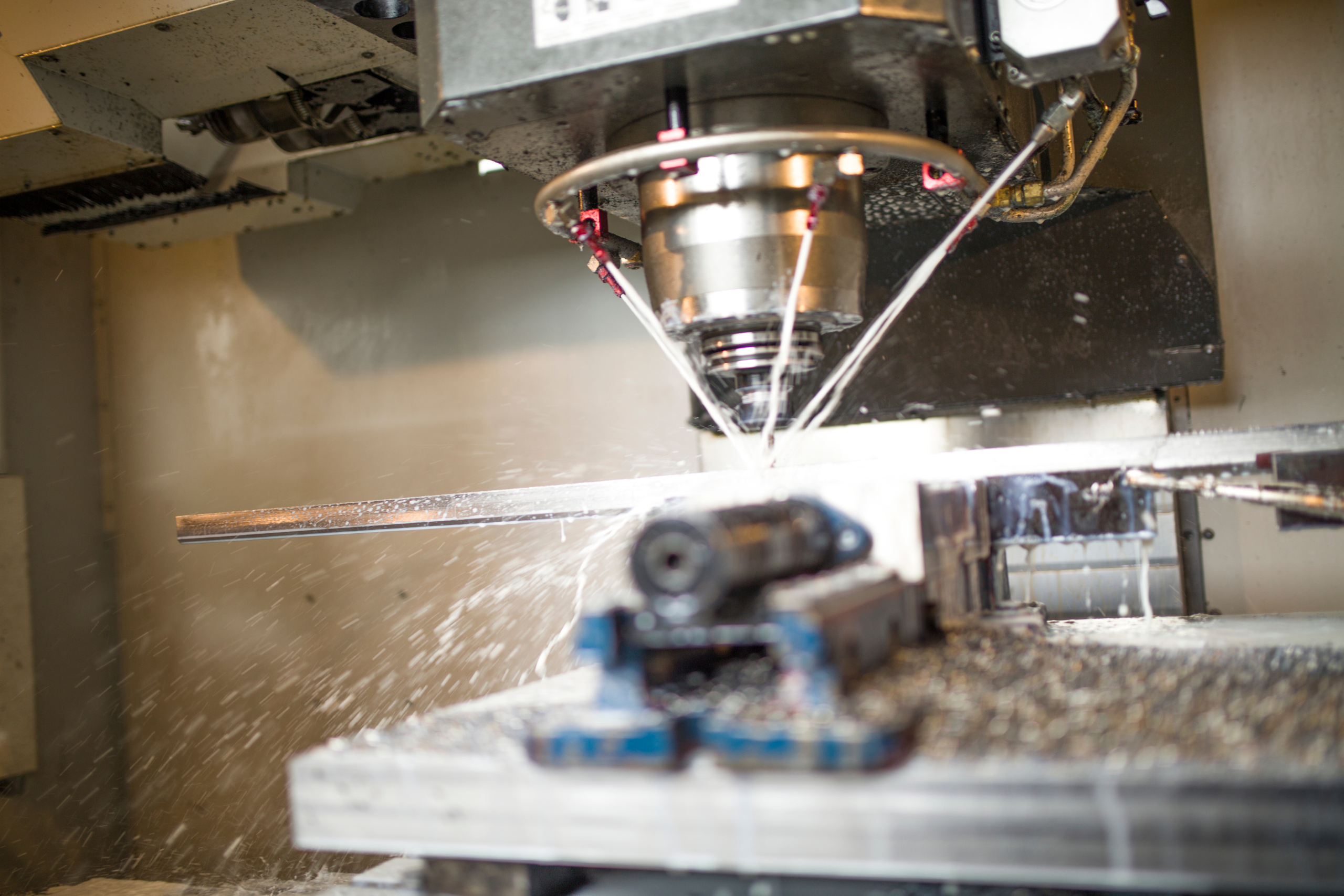

Before we dive into the benefits of a high-quality base shell, let’s first understand what a base shell is. A base shell is a cylinder made of a variety of materials, including steel, aluminum, and copper. It serves as the foundation for the engraving process, which creates the image that will be printed onto the substrate. The base shell is engraved with tiny cells of varying depths and widths, which hold the ink that will be transferred onto the substrate during the printing process.

How a High-Quality Base Shell Can Benefit Your Rotogravure Printing Process

- Better Print Quality

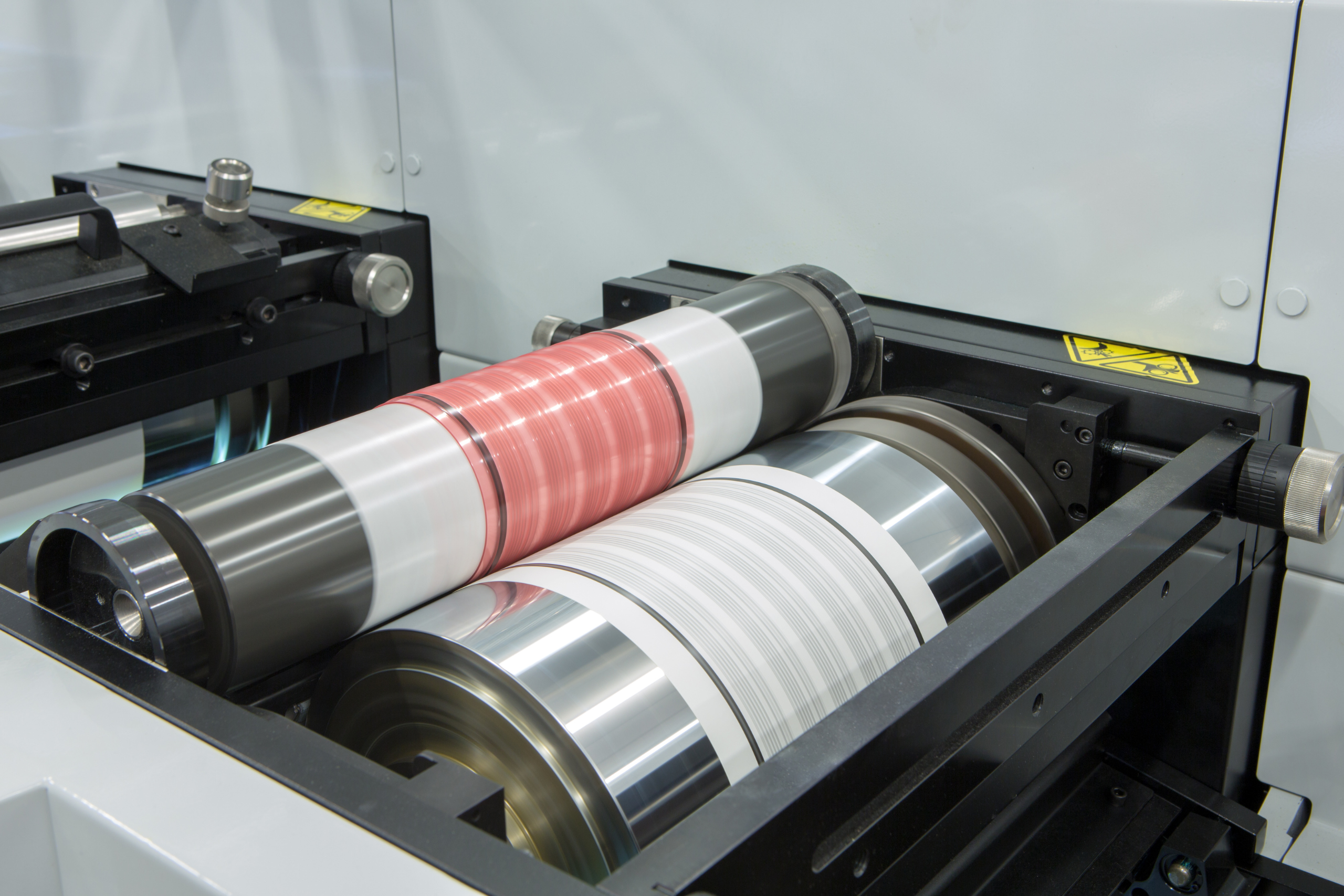

The primary benefit of a high-quality base shell is better print quality. A well-made base shell will have consistent cell depth and width, resulting in more accurate and consistent ink transfer onto the substrate. This leads to sharper images, better color saturation, and more precise registration between colors. A high-quality base shell also reduces the risk of ink pooling or smudging, resulting in a cleaner and more professional-looking print.

- Longer Life Span

A high-quality base shell will have a longer life span than a lower-quality one. This means less downtime for maintenance and repairs, resulting in increased productivity and reduced costs. Additionally, a longer life span means that the base shell will maintain its consistency over time, ensuring consistent print quality throughout the life of the cylinder.

- Reduced Waste

A high-quality base shell can help reduce waste in the printing process. Consistent cell depth and width mean less ink is required to fill the cells, resulting in less ink waste. Additionally, a well-made base shell reduces the risk of print defects, which can lead to scrapped prints and wasted materials.

- Faster Printing Speeds

A high-quality base shell can lead to faster printing speeds. A well-made base shell ensures consistent ink transfer, reducing the need for frequent adjustments and resulting in faster printing speeds. This leads to increased productivity and reduced costs.

- Customization

A high-quality base shell can be customized to meet specific printing needs. The cell shape and size can be tailored to the specific substrate and ink being used, resulting in better print quality and reduced waste.

Conclusion

A high-quality base shell can revolutionize your rotogravure printing process. The benefits of a well-made base shell are clear: better print quality, longer life span, reduced waste, faster printing speeds, and customization options. By investing in a high-quality base shell, you can improve your print quality, increase productivity, and reduce costs.