How a High-Quality Base Shell Can Revolutionize Your Rotogravure Printing Process

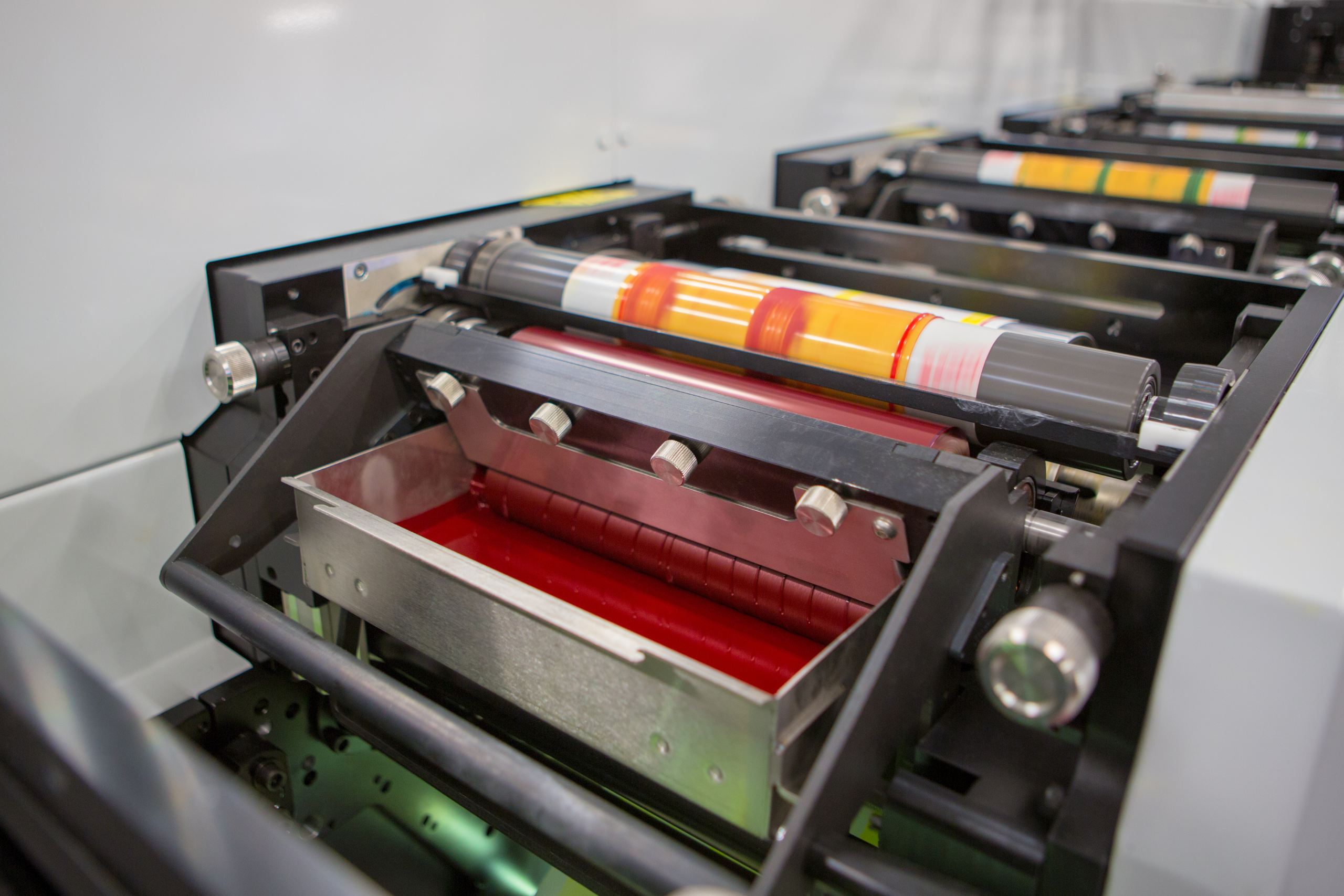

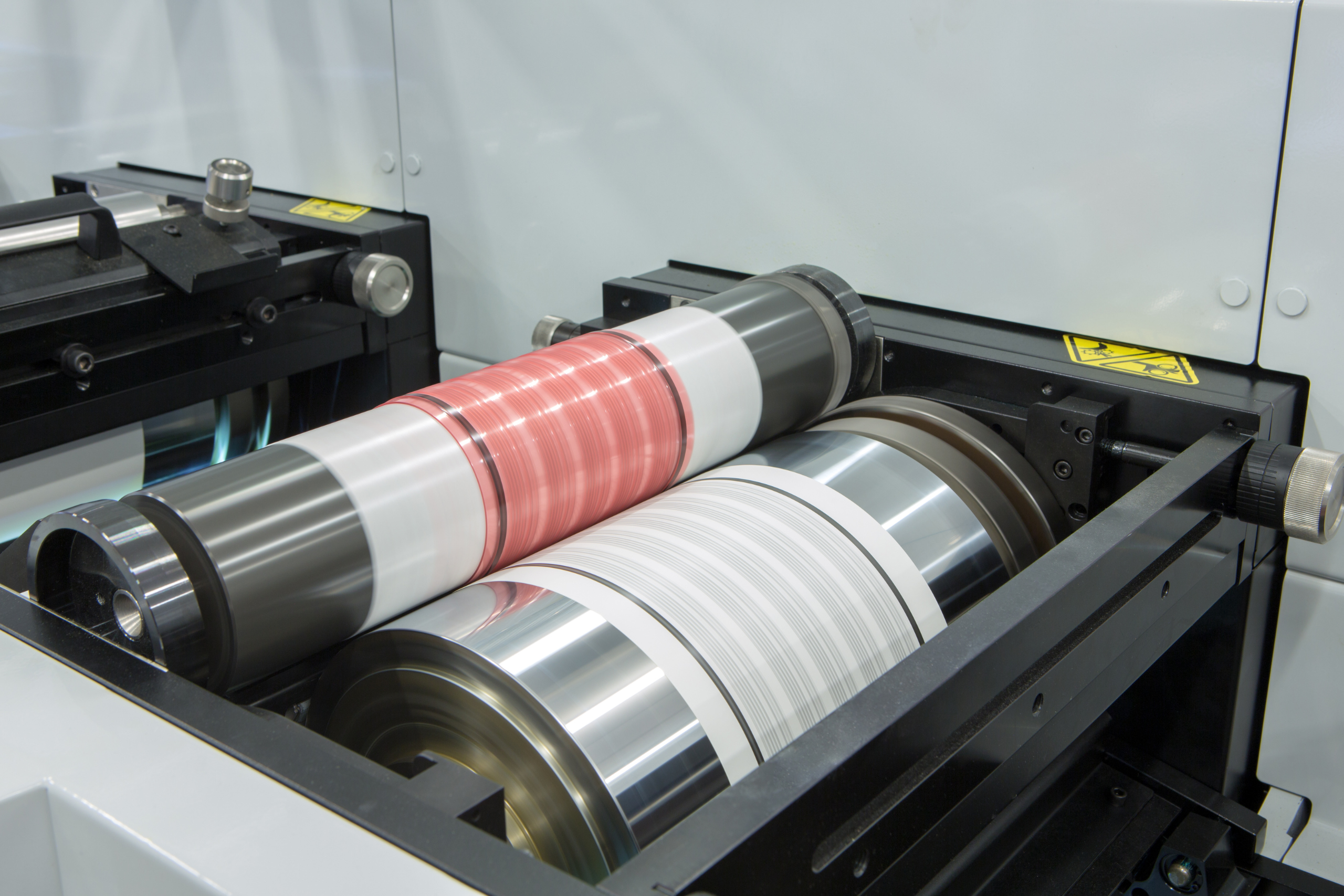

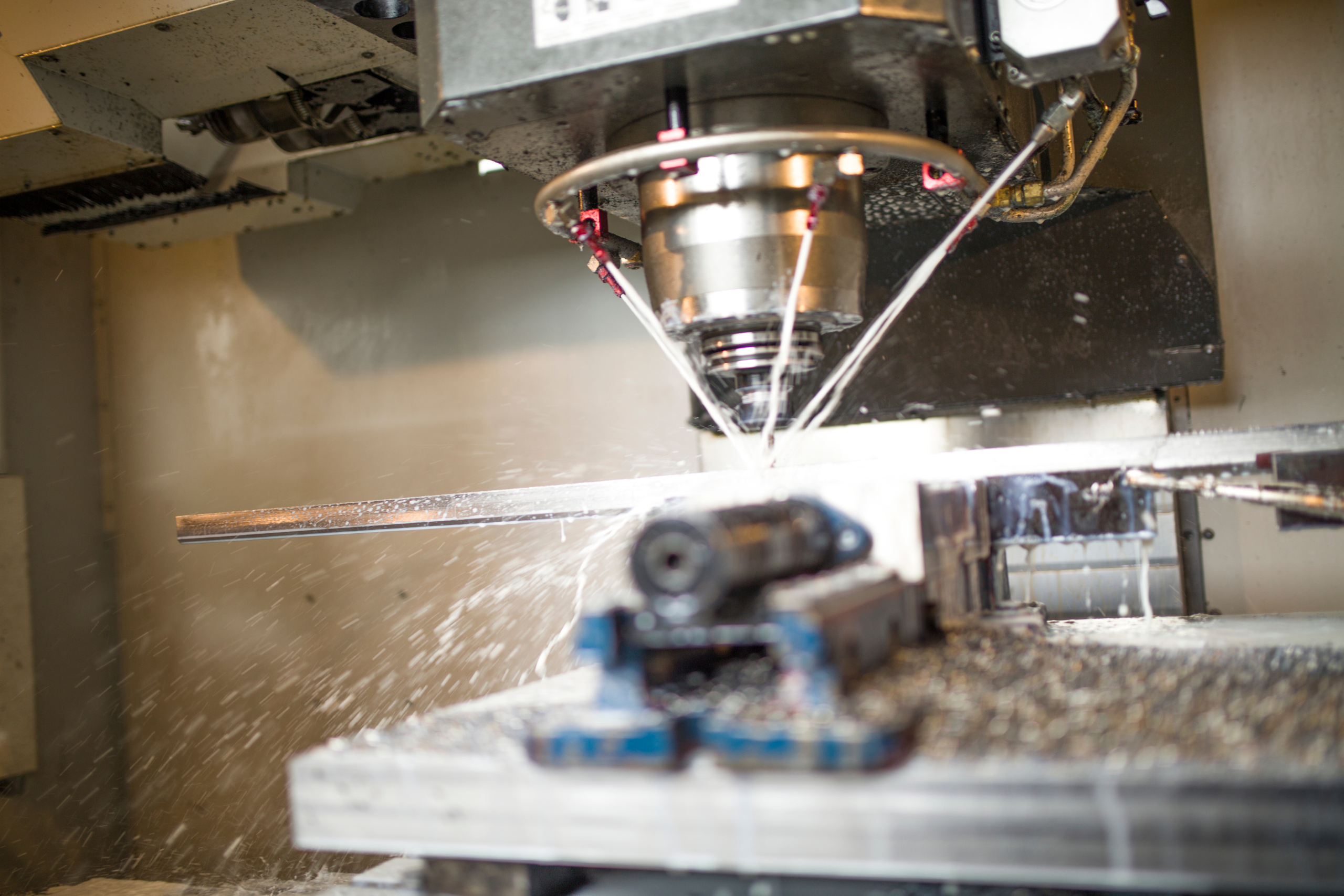

Rotogravure printing is a widely used printing process that utilizes an engraved cylinder to transfer ink onto a substrate. The quality of the engraved cylinder, or more specifically the base…